Fire Retardant Intumescent Coatings in Irving, TX

Certified fire-rated coatings for safety compliance.

Technical

Specifications.

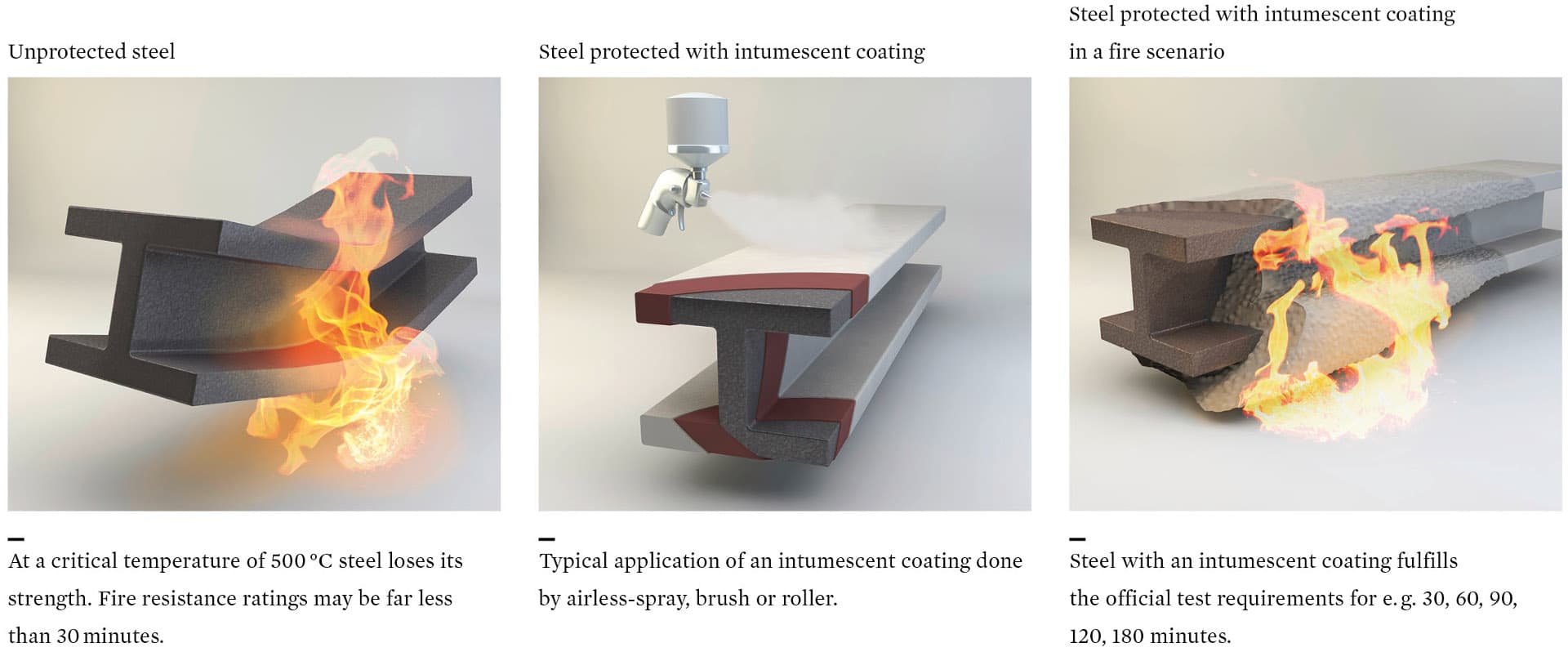

Commercial Painting Contractors Irving provides specialized fire retardant and intumescent coating systems engineered to protect structural steel, wood framing, and building assemblies from fire damage in commercial, industrial, and institutional facilities throughout the Dallas-Fort Worth area. Our fire protection specialists bring deep technical expertise in UL-listed systems that expand when exposed to heat, creating insulating barriers that prevent temperature rise in structural members and maintain load-bearing capacity during fire events. We understand that fire protection coatings are critical life-safety systems requiring precise application according to strict manufacturer specifications and building code requirements. Serving Irving's commercial construction market, building renovation projects, and facilities requiring fire rating upgrades, we deliver certified fire protection systems with comprehensive documentation supporting code compliance, insurance requirements, and occupancy approvals.

UL-listed intumescent coating systems for steel and wood

Fire ratings from 1-hour to 4-hour protection

Thin-film and thick-film intumescent applications

Cementitious fireproofing for heavy-duty applications

Fire-retardant treatments for wood and cellulosic materials

Code compliance documentation and certification

Coordination with building inspectors and fire marshals

Quality control and dry film thickness verification

Irving

Context.

Based in Irving, we serve the fire protection requirements of commercial construction throughout Las Colinas's growing skyline, industrial facilities requiring fire-rated structural protection, institutional buildings meeting stringent life-safety codes, and renovation projects where existing structures require fire rating upgrades to meet current codes. Our teams navigate the regulatory landscape of Irving and Dallas-Fort Worth building departments, understand the fire protection requirements specific to various occupancy classifications, and maintain relationships with code officials facilitating smooth inspection and approval processes.

Specify Your Project

Strategic

Advantages.

Life-safety protection maintaining structural integrity during fire events

Building code compliance supporting occupancy permits and insurance approval

Reduced insurance premiums through certified fire protection systems

Architectural flexibility preserving exposed steel aesthetics while meeting fire codes

Long-term durability with minimal maintenance compared to other fireproofing methods

Faster construction schedules compared to traditional fireproofing enclosure

Comprehensive documentation supporting building inspections and insurance audits

Our Proven

Process.

Fire protection assessment determining required ratings and appropriate systems

UL system selection matching specific structural configuration and rating requirements

Surface preparation to manufacturer specifications ensuring proper adhesion

Precise application achieving specified dry film thickness per UL listing

Multiple coat application as required by fire rating and UL system design

Quality control verification of dry film thickness at prescribed sampling rates

Documentation package including material certifications and application records

Frequently Asked

Questions.

What's the difference between intumescent and cementitious fireproofing?

Intumescent coatings are thin-film systems (typically 10-100 mils) that expand when exposed to heat, creating insulating foam that protects steel. They maintain architectural aesthetics, are lighter weight, and work well for exposed structural steel. Cementitious fireproofing is thick, cement-based material sprayed onto steel—very effective but heavy and aesthetically unsuitable for architectural applications. Intumescent systems dominate commercial applications where exposed steel finish is desired while meeting fire protection requirements.

How long do fire retardant coatings last?

Properly applied intumescent systems typically maintain fire protection properties for 25+ years in interior applications. Exterior intumescent systems require topcoating for weather protection and periodic inspection. Cementitious fireproofing is essentially permanent barring physical damage. Building codes don't require re-application unless damage occurs, but periodic inspection every 5-10 years ensures coating integrity. Manufacturers provide long-term warranties when systems are applied per UL listings.

Can intumescent coatings be painted over for aesthetics?

Yes, most intumescent systems allow topcoating with compatible paints. However, any topcoat must be approved by the intumescent manufacturer and not exceed maximum dry film thickness specified in the UL listing—excessive topcoat can prevent proper intumescent expansion. We coordinate topcoat selection ensuring fire protection integrity while achieving desired aesthetics. The complete system including topcoats must match the tested UL assembly.

What documentation is required for building inspection approval?

Building inspectors require comprehensive documentation including UL system design number matching structural configuration, manufacturer's product data sheets and application instructions, material certifications showing products match UL listing, dry film thickness measurements verifying proper application, and applicator certification demonstrating trained personnel. We provide complete documentation packages satisfying inspection requirements and supporting permanent building records.

How do you ensure proper fire rating is achieved?

Fire rating achievement requires strict adherence to UL system specifications. We verify structural configuration matches UL design (member size, spacing, etc.), calculate required dry film thickness based on W/D ratio per UL listing, apply coatings to manufacturer specifications including temperature and humidity requirements, verify dry film thickness using magnetic or ultrasonic gauges at prescribed sampling rates, and maintain records demonstrating compliance. We never deviate from UL listings—proper application is critical for life-safety performance.

Can existing steel structures be upgraded with fire protection?

Absolutely. Many renovation projects require fire rating upgrades to meet current codes or change occupancy classifications. Existing steel must be properly prepared—removing loose rust, oils, and contaminants. We assess existing conditions, recommend appropriate UL systems for retrofit applications, coordinate with structural engineers verifying rating requirements, and apply systems meeting code requirements. Retrofit fire protection is common in building conversions, occupancy changes, and code upgrade projects.

What fire ratings are available for different applications?

Intumescent systems provide ratings from 30 minutes to 4 hours depending on structural configuration and coating thickness. Common commercial applications: 1-hour rating for interior steel in typical construction, 2-hour rating for occupancy separations and exit stairways, 3-hour rating for high-rise buildings and high-hazard occupancies, and 4-hour rating for special applications. Required rating depends on building code, occupancy classification, and structural use. We help navigate these requirements and specify appropriate systems.

Project Lifecycle

Typical deployment timeline for Irving facilities.

Evaluation

Day 1-2Substrate analysis and detailed specification development.

Mobilization

Day 3-5Site protection, equipment setup, and material procurement.

Execution

VariesMulti-layered coating application with phased deployment.

Validation

Final DayQuality audit, walk-through, and site demobilization.

Evaluate

Your Asset.

Whether you possess a single corporate unit or an entire industrial complex, our professional team is prepared to develop your project specifications.